Equipment for Dynamic Testing

Engenuity Drop Tower & Crush Fixture

We offer two pieces of equipments for dynamic testing – The Drop Tower & Crush Fixture. Both are custom-designed for high energy, accuracy and speed.

Engenuity’s state of the art Drop Tower impact test machine was fully designed in-house and has been through numerous prototype variations to get it to the world leading test machine of its type with easily removable masses to adjust energy output up to 4.6 kJ. Custom hardware and software available to process your data and speed up coupon preparation.

Our solutions are available to purchase or license and we offer world class support to get you up and running.

Contact us now and learn how we can improve your laboratory

Drop Tower

A drop tower dynamic testing machine is used to determine the energy required to break or damage a material in which a defined weight falls onto a specimen or a component from a specific height and with a specific impact energy and velocity.

It is highly controlled impact testing developed for high accuracy and fast turnaround of composite samples. It includes a software which assesses the suitability of materials for dynamic applications.

Drop Tower Test Machine for Dynamic Testing

The Increasing Need for Dynamic Testing

The Engenuity drop tower has been developed for exactly this purpose, giving high accuracy and fast turnaround times for many key composite dynamic properties.

System Features

Range of Tests

Impact testing, Crush testing, dynamic compression testing, bespoke component drop impact testing.

Optional Upgrades

- Crush stress – delamination free

- Crush stress – delamination suppressed

Technical Specifications

Overall Dimension :

W: 150cm wide

D: 110cm depth with door closed , 170cm depth with door open

H: 300cm not including foundations

Data Acquisition Rate & Points :

– High speed data acquisition (up to 500 kHz)

– Typical test can be over as quick as 60 microseconds (Dynamic Compression), however the system will record for up to 1 second (500,000 data points) and the area of interest can be selected after the test

Overload Capacity :

100% of the Drop Energy can be put into the base in the event of a component failure that does not absorb the energy that is expected

High Speed Camera Trigger :

-Integrated optical camera bar, camera adjuster tower and electronic trigger to conduct high speed photography and facilitate Digital Image Correlation (optional)

Load Measurement :

± 100kN Pancake Dynamic Loadcell with High Speed Amplifier

Touch Screen :

24” Touch Screen mounted to the Drop Tower frame

Operative System :

Windows 10 / 11 Professional with Data Acquisition Software pre-installed

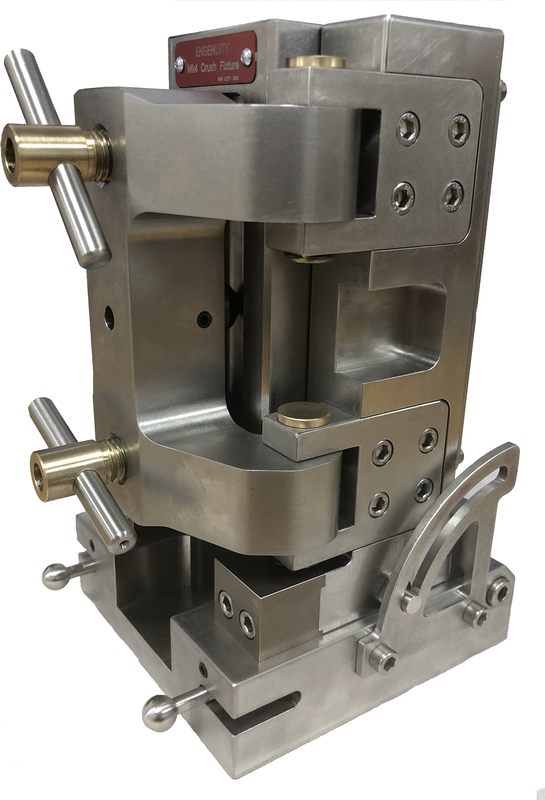

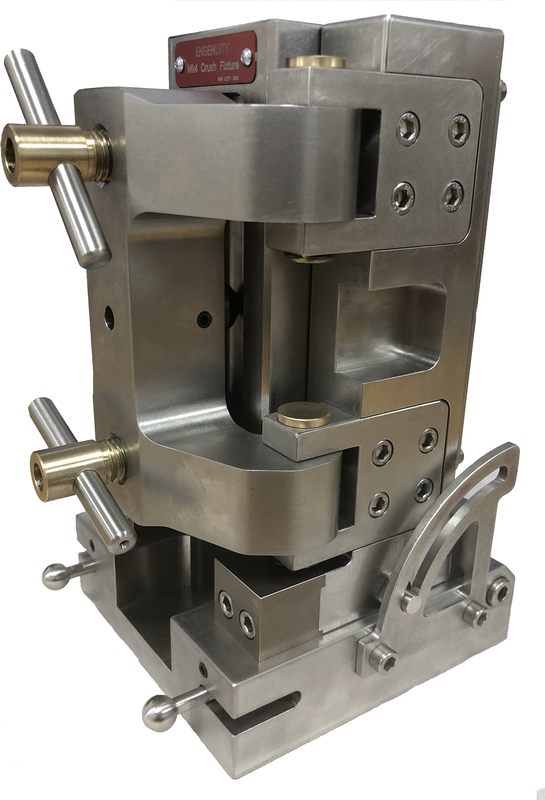

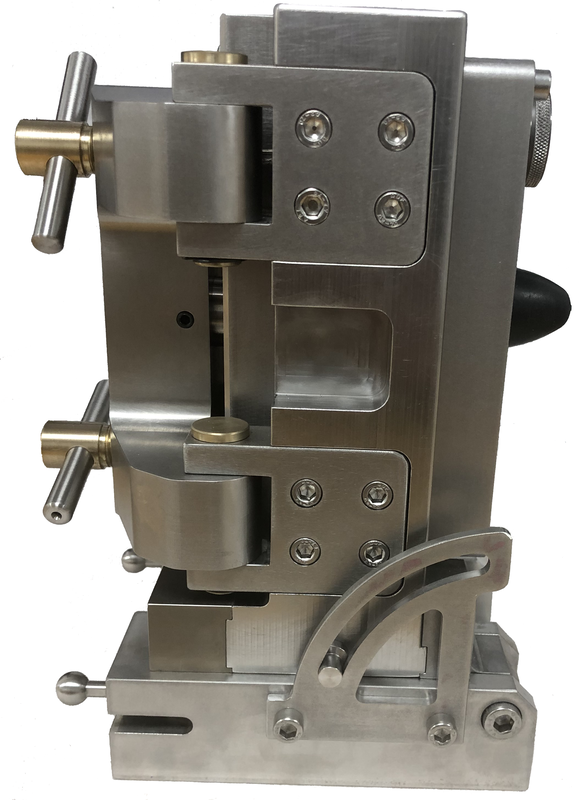

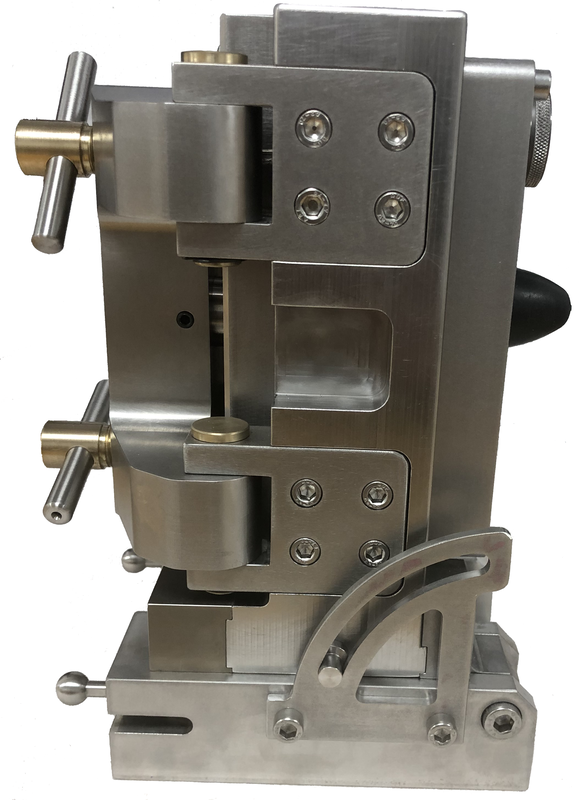

Crush Fixture

SYSTEM FEATURES

The Engenuity crush fixture has been designed for high throughput, consistency of results and ease of use. It’s portable and can be installed in compression testers or drop towers to gain both static and dynamic results. The Crush Fixture also allows both de-lamination free & de-lamination suppressed failure modes from flat coupons for inputting into CZone.

Overall Dimension :

W: 180 mm; D: 190mm ; H: 240 mm

For a detailed information on this see our page on Crush Stress & SEA Testing

Our network of experienced sales engineers at Engenuity are happy to assist you with any question on the use of these equipments. With over 30 years of experience, our team will find the configuration that will perfectly fit your needs.

Contact us now and learn how we can help you improve your Laboratory